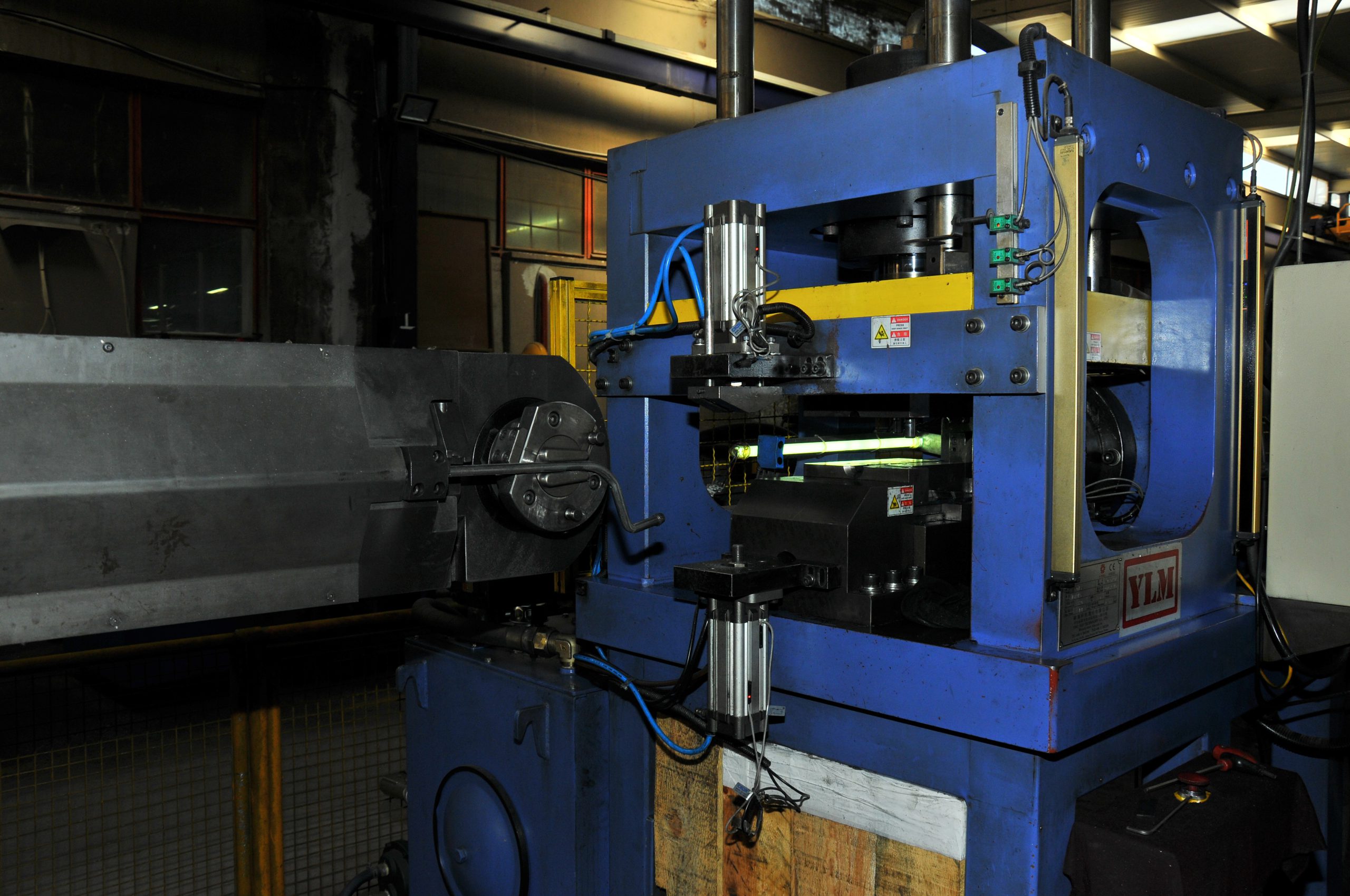

The annual production capacity of silencers and pipes produced in Ağar Oto Egzoz San Tic.A.Ş. is approximately 350.000. Aluminum-coated pipes of various diameters and thicknesses, galvanized and aluminum-coated sheets of various thicknesses are used in production. The production line has been redesigned according to the flow of the process and unnecessary transportation and labor are minimized from raw material input until the product is put up for sale. Sheet metal, one of the raw material inputs, is cut according to the work order and instructions given in the guillotine shears. These cut sheets pass through the presses and silencer machines and form the body part of the exhaust system. In pipe section, on the other hand, pipes pass through various processes such as cutting, bending, mouth expansion, angled cutting, nickel plating, and they form the pipes of the exhaust system.

All parts of the exhaust system are assembled on the assembly line and after cleaning in the paint shop, they are offered for sale. The necessary quality control as well as statistical controls are carried out at every stage of production. The most important of the benches required for the production are the "CNC controlled benches" which are used by the worldwide known companies. Ağar Oto Egzoz San Tic.A.Ş. manufactures all the necessary parts (such as flange, connection, etc.) for the exhaust system within its own body. All of the moulds used in Ağar Oto Egzoz San Tic.A.Ş. benches are also made in its own moulding room.

Moulds are made on CNC machines by means of using CAD-CAM (CIMATRON) system. Ağar Oto Egzoz San Tic.A.Ş. has established its quality assurance system in accordance with ISO 9001 requirements. It is certified in order to fully prove the specified specifications and requirements of products and services. The main purpose of the quality system is to provide an effective management system by carrying out all activities in a planned and harmonious manner and also to provide production and service, at the lowest costs without sacrificing its quality.